The fasteners guide for installing cedar shakes and shingles

How to ensure your cedar installation lasts for decades

The most overlooked — and also most crucial — element of any cedar shakes or shingles installation project is fasteners. Not all fasteners are created equal. In fact, these relatively small components of a project are the difference between a successful, decades-long installation, and a project that requires redoing in just a few short years.

This detail affects everything. Fasteners are the crucial element of keeping cedar looking and functioning at its absolute best. This guide will help you select the right type and quantity for your project.

Where is the shake or shingle installation?

Cedar shakes and shingles are installed either on a roof or sidewall. Weather delivers more wear and tear on a roof than a sidewall, therefore only nails are recommended for roofing installation.

Staples are absolutely not recommended for roofing. If the project will not be exposed to hurricane-force winds, staples can be a good solution for installing sidewall, but nails are still preferred.

What type of material should the fasteners be?

What kind of stainless steel should be used?

There are two kinds of stainless steel: 304 stainless and 316 stainless. 304 provides some protection, but 316 stainless offers far superior protection in the material. 316 tends to be more expensive than 304. Imported 304 stainless nails are much more readily available. However, domestic 316 nails offer the highest level of protection.

316 stainless is required when installation is:

Within 15 miles of saltwater,

When the roof is treated with fire retardant,

When the roof is treated with CCA, or

In cases of some additional building codes or requirements.

How deep should I drive the nails?

The total length of the nail you choose should take into account the following:

A minimum 3/4” of the nail is driven into the roof deck. For example, if a shake roof were installed on 1/2” plywood, the nail would need to stick through the roof deck at least 1/4”. Super-long nail lengths are also discouraged, based on aesthetics and the homeowner’s plans for their attic space.

Additional spacing for cedar breather and/or underlayment layers. When installed, cedar breather adds 1/4” to the thickness that the nail must penetrate. While 1-1/4” nails are the minimum for cedar shingles, if a cedar breather is used, then 1-1/2” nails are the minimum length.

Additional insulation. Rigid insulation can require additional length for the nail.

Thickness of the shake or shingle. The installation line varies among shakes.

Any additional building codes. Requirements for lengths of fasteners vary among municipalities and regions. Always check your local codes.

Should I hand-drive nails or use a nail gun?

Hand drive has been the industry standard for years. Experienced shake roofers are able to install shakes by hand at shockingly quick speeds.

However, most installers have switched to nail guns. Since the length of the nails on cedar shingles and shakes tends to be longer than nails used for asphalt shingles, installers will often use siding nailers.

Be careful when using a nail gun, as the pressure of the nailer could unintentionally split the shakes. Installers typically need to use lower pressure than what most asphalt roofers are used to.

Nail guns have different degree ratings, and only some coiled nails are compatible with certain nailers. You should know what kind of guns your crew uses, and then determine what kind of coiled nails are compatible.

Not sure what to use? We can help you make a decision that will work for your crew.

How many nails per bundle?

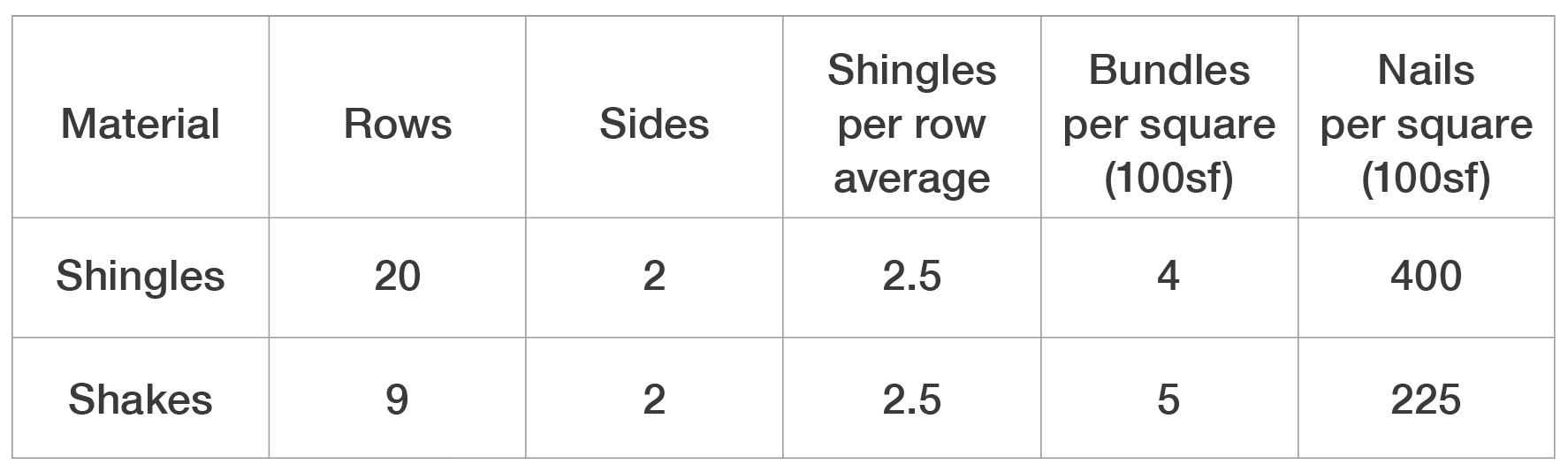

Each cedar shake or shingle requires only two nails. The most common ways of packing shingles is in 20-rowed bundles. The most common way of packing shakes are 9-rowed bundles.

No. 1 shingles and shakes tend to have wider shakes, so fewer nails are required than No. 2 material. That said, you can approximate how many nails you need for your project:

Additional information

Both of these resources are provided by the Cedar Shake & Shingle Bureau.

How can we help you?

We’re so passionate about getting the job done right that we wrote this guide. And there’s a lot more expert knowledge and friendly, helpful advice where that came from. We can help you identify a shingle or shake milled 40 years ago — and sourcing its perfect match for a repair job. We provide competitive and informative bids, to ensuring you get your order right the first time around.

Give us a call at 541-868-8390 to help with your next project.